- Home

- Business Optimization

- Design Center

- Post-installed Rebar Solutions

Post-Installed Rebar Solutions

Safer, faster & more flexible solutions for post-installed rebar

At Hilti, we know how important it is to get rebar right the first time. With looming deadlines and health and safety guidelines to follow, you can’t afford any costly mistakes – whether that’s incorrect installation or staff shortages due to illness and injury. With Hand Arm Vibration Syndrome (HAVS) and silica dust posing a risk to workers, a safer alternative to traditional methods is needed to protect employees and their employers. We also understand how challenging it can be when your design programme isn’t compatible with other software suites, or when you’re limited to standard applications with inflexible designs. Well, you spoke and we heard! Let’s take a look at our post-installed rebar solutions…

Rebar product solutions

HIT-RE 500 V3

Ultimate-performance injectable epoxy mortar with approvals for rebar connections and heavy-duty anchoring.

Shop nowHIT-HY 200 V3

Ultimate-performance injectable hybrid mortar with approvals for anchoring structural steel baseplate and post-installed rebar connections.

Learn moreHDE 500-22 cordless dispenser

Battery-powered hybrid/epoxy adhesive anchor dispenser with smart features to help increase speed, safety and reduce waste.

Shop nowCordless rotary hammers

With Hilti cordless rotary hammers you can work faster, obtain better installation quality and help boost jobsite safety with virtually dust-free hole cleaning.

Learn more

MINIMISE THE RISKS

Reduced vibration & virtually dust-free drilling

Want to increase worker safety and help prevent painful disorders like HAVS? Thanks to Active Vibration Reduction (AVR), our rotary hammers – even the powerful TE 60 and TE 70 – produce lower vibrations, which help to minimise the risk of permanent damage.

But what about the dust that comes from drilling and manual hole cleaning? Inhaling silica dust can be fatal, which is why we’ve developed SafeSet – a virtually dust-free solution that replaces traditional drilling and blow-brush-blow cleaning. Simply attach our VC 20/40 concrete dust vacuum to our TE-CD or TE-YD hollow drill bit, and the dust will be removed automatically without any human contact – making the process much safer.

SAVE TIME, BOOST PRODUCTIVITY

Skip steps with automatic hole cleaning

Incorrectly installing rebar is not only dangerous but can cost you time and money having to right those wrongs in the future. The most common mistake is poorly cleaned holes, which can lead to anchor failure if the chemical mortar doesn’t set properly. Our SafeSet system helps to prevent this, by automatically cleaning the holes so the rebar is correctly installed first time. And because it drills and cleans simultaneously, you can skip the blow-brush-blow step altogether – saving you time so the job gets done quicker.

You can also minimise expensive project delays by pinpointing rebar in concrete before you start, which reduces the risk of accidental damage to existing reinforcements. The Hilti PS 300 Ferroscan can quickly and precisely locate this rebar – speeding up drilling work and boosting productivity. And for even faster resin injection, our battery-operated HDE 500-A22 mortar dispenser gives you the control you need to accurately dispense adhesive.

ENGINEERED SOLUTIONS THAT WORK

Flexible design & seamless integration

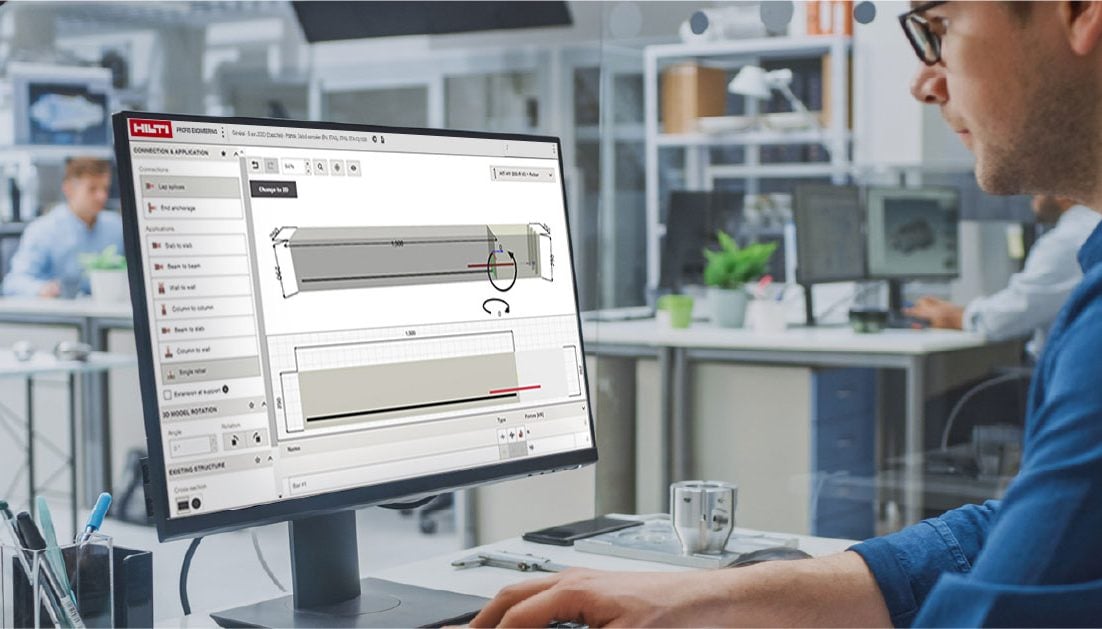

What if you could integrate your rebar design programme into your other design software suites? With PROFIS ENGINEERING, you can! Not only does it link straight to the Hilti BIM/CAD library, but it also integrates seamlessly with AutoCAD® and Revit® design software. And because it has a fully flexible design, it can even be used for non-standard applications where there are variable embedment depths, load types, drilling methods and conditions. Plus, you’ll never have to worry about compliance as it’s based on the latest model building codes and regulations including Eurocode 2 and ACI.